/ /AluminumCasting /MechContrSyst /ParametricSlicing /AluminumCarving /Thermodynamics /FEA /SPE3Dprinting /ElectricMotorcycle /3dPressureSensingHotend /PopsicleBridge /Ramjet /ModelSterling /3DPrintedDiscGolf /Bonsai /DamascusRing /Drawings /MetropolisFEA /Python /Ceramics

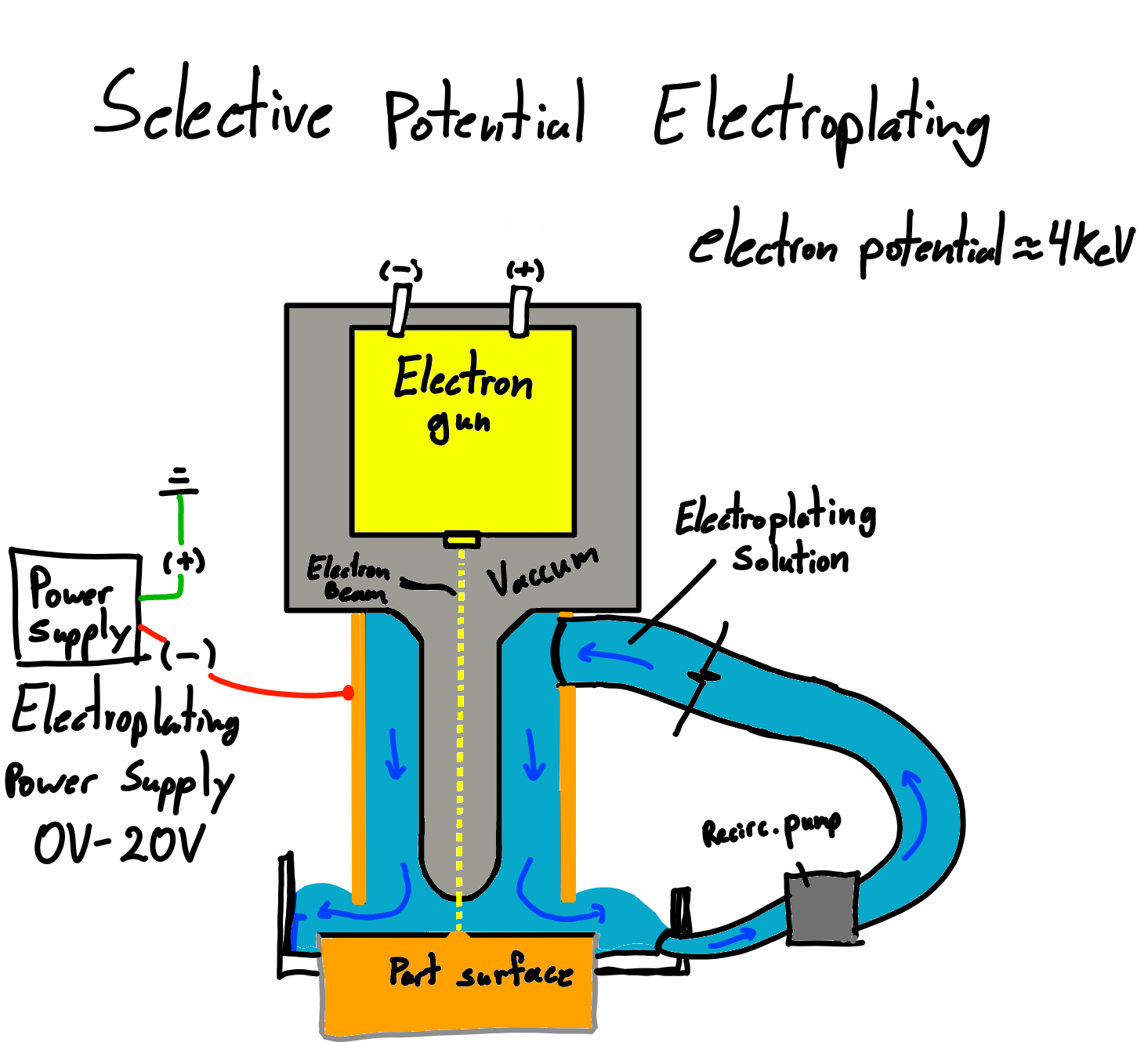

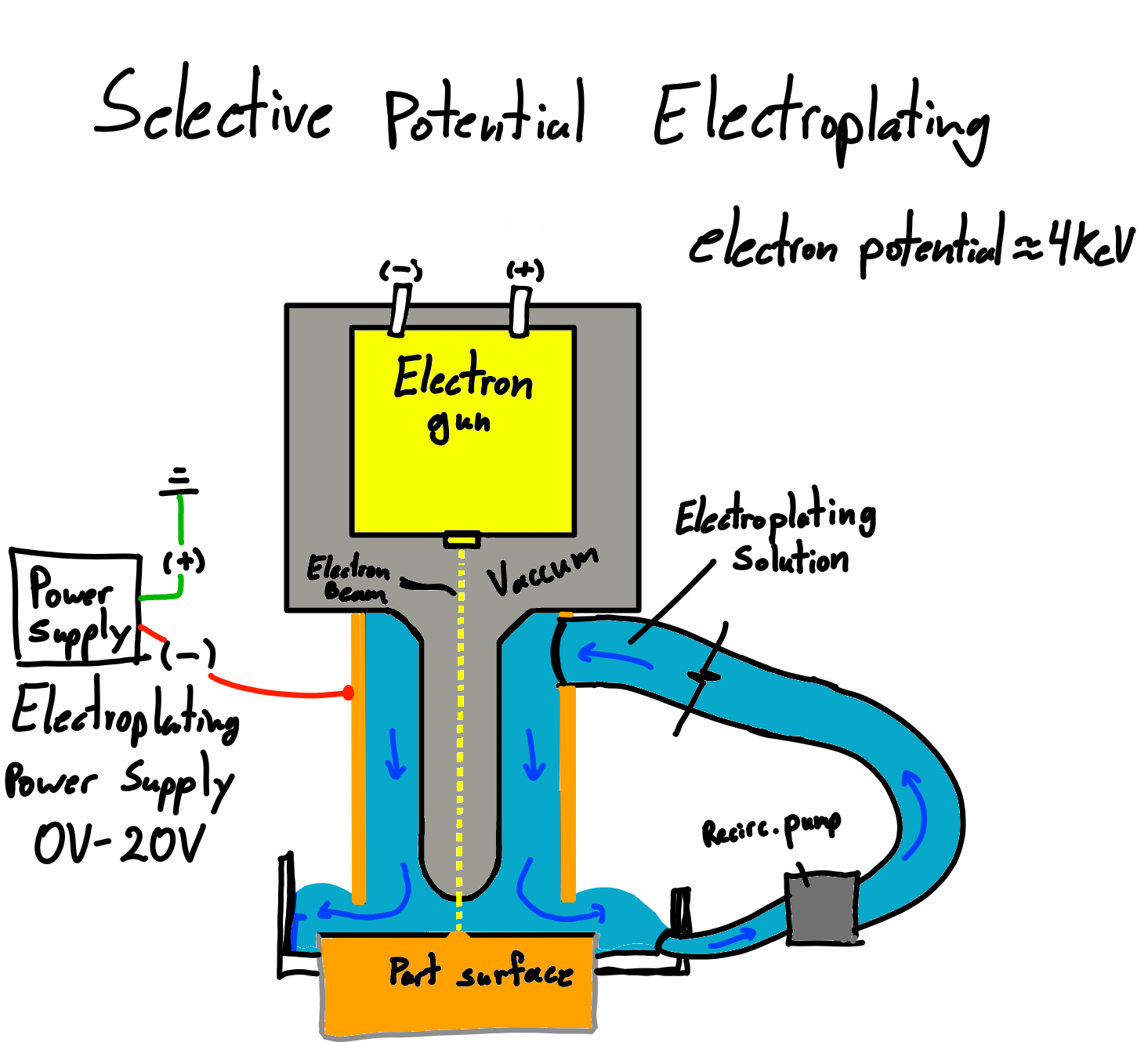

I'm thinking of calling this Selective Potential Electroplate 3D printing SPE3D printing lmao... I find that very amusing. One of the biggest issues that I see with 3d printing metal is that the required cooling is very challenging. There are many ways to heat something up enough to combine them but to cool them down quickly enough to maintain high dimensional accuracy is an issue. Instead lets consider electroplating, it is used in some 3dprinting designs so it is a possibility. Electroplating occurring in water should make things a bit easier to control heat and accuracy. But the trade-off I think is that it is hard to get high printing rates, I'll leave that for future consideration. The idea is to use an electron gun to place electron on any surface and cause electroplating to occur there at that site. The electrons thus create a potential around where they are hitting and should cause plating to occur there. With a low amperage and well defined focal point this should have exceptional accuracy. By turning up the amperage of the electron gun there should be a much higher deposition rate over a bit larger area. The electrons will need to have a speed of about 4KeV to drill through the designated area of vacuum chamber wall and get through the electroplating solution and reach a surface. Through thickness of vacuum chamber glass and electroplating solution there should be a distance of ~2mm. This is because the approximate loss of energy of the electrons is ~1.6MeV/cm. Roughly the same loss through the applicable material choices here. There is the issue of X-ray generation. I'm not super versed here but X-ray generation, I believe, is higher for electron interactions with heaver atoms. Going though water should not be terrible, but hitting the plating surface will generate quite a few so proper sheilding would be required. For the 4KeV X-rays generated should be absorbed to ~90% with just 2.3cm of copper or 23cm of water. The addition of sheilding in the machine enclosure should bring any X-rays to acceptable levels. X-ray generation will be linked to print speed/amount. Using the electron beam to drill a hole through the vacuum chamber and prime the electron path would require that the chamber be continuously vacuumed down. Would there be problems still? very probably. Should the electrons be focused at the vacuum chamber surface or the surface of the part? I guess it greatly depends on the resolution that is required, the focal length of the electron beam, and how well the vacuum pump is able to take care of ingressing water/ contaminates... I do not know, it might just need to be done and evaluated at that point. Being able to scan across the part would also be really nice since it is an electron beam and relatively easy to steer, but we run into issues with needing a vacuum over the whole area which removes the possibility of electroplating solution... One thing at a time.

email: va.web.code@gmail.com https://github.com/va-code https://www.youtube.com/@vaughnanderson7984