/ /AluminumCasting /MechContrSyst /ParametricSlicing /AluminumCarving /Thermodynamics /FEA /SPE3Dprinting /ElectricMotorcycle /3dPressureSensingHotend /PopsicleBridge /Ramjet /ModelSterling /3DPrintedDiscGolf /Bonsai /DamascusRing /Drawings /MetropolisFEA /Python /Ceramics

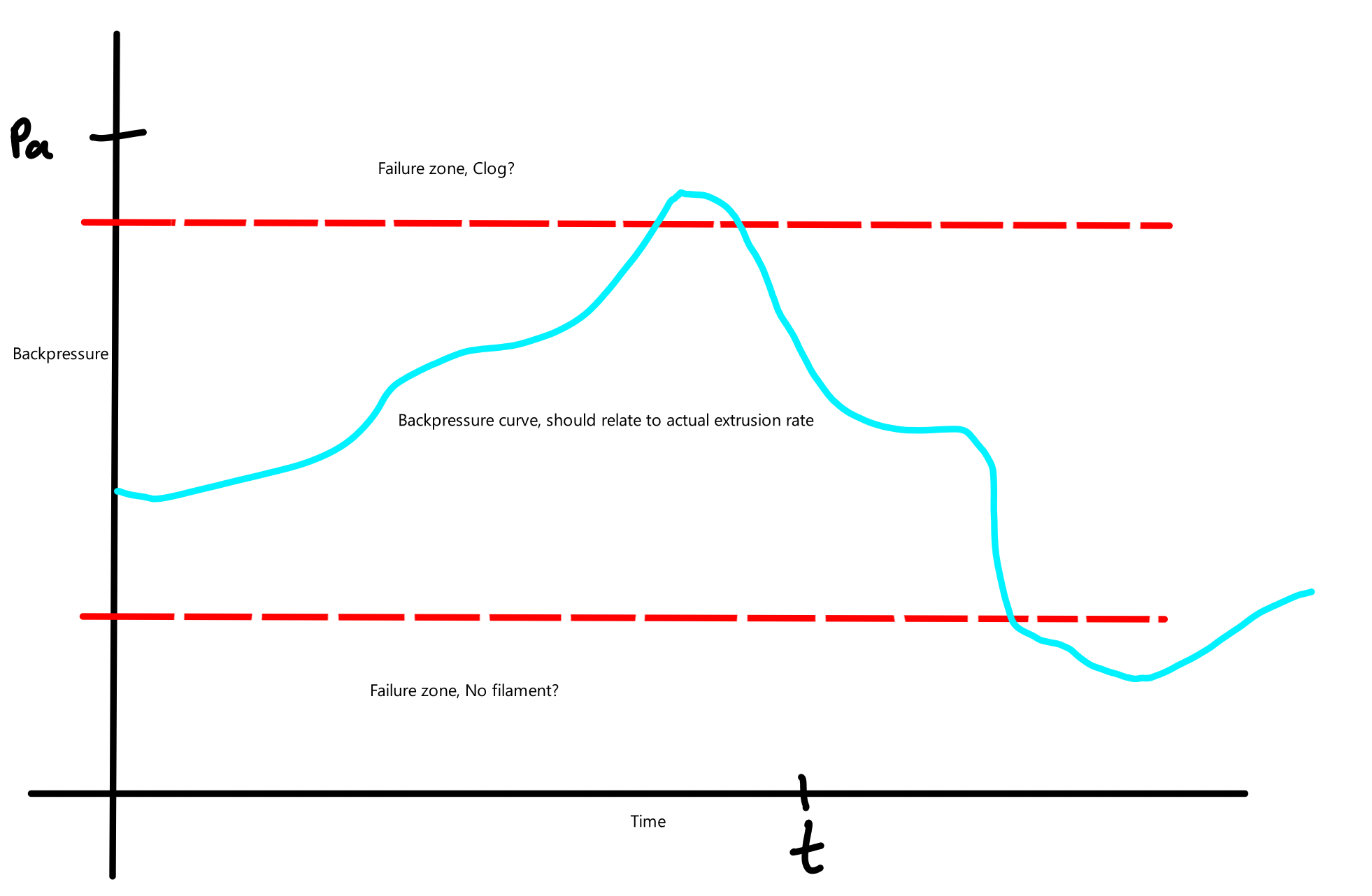

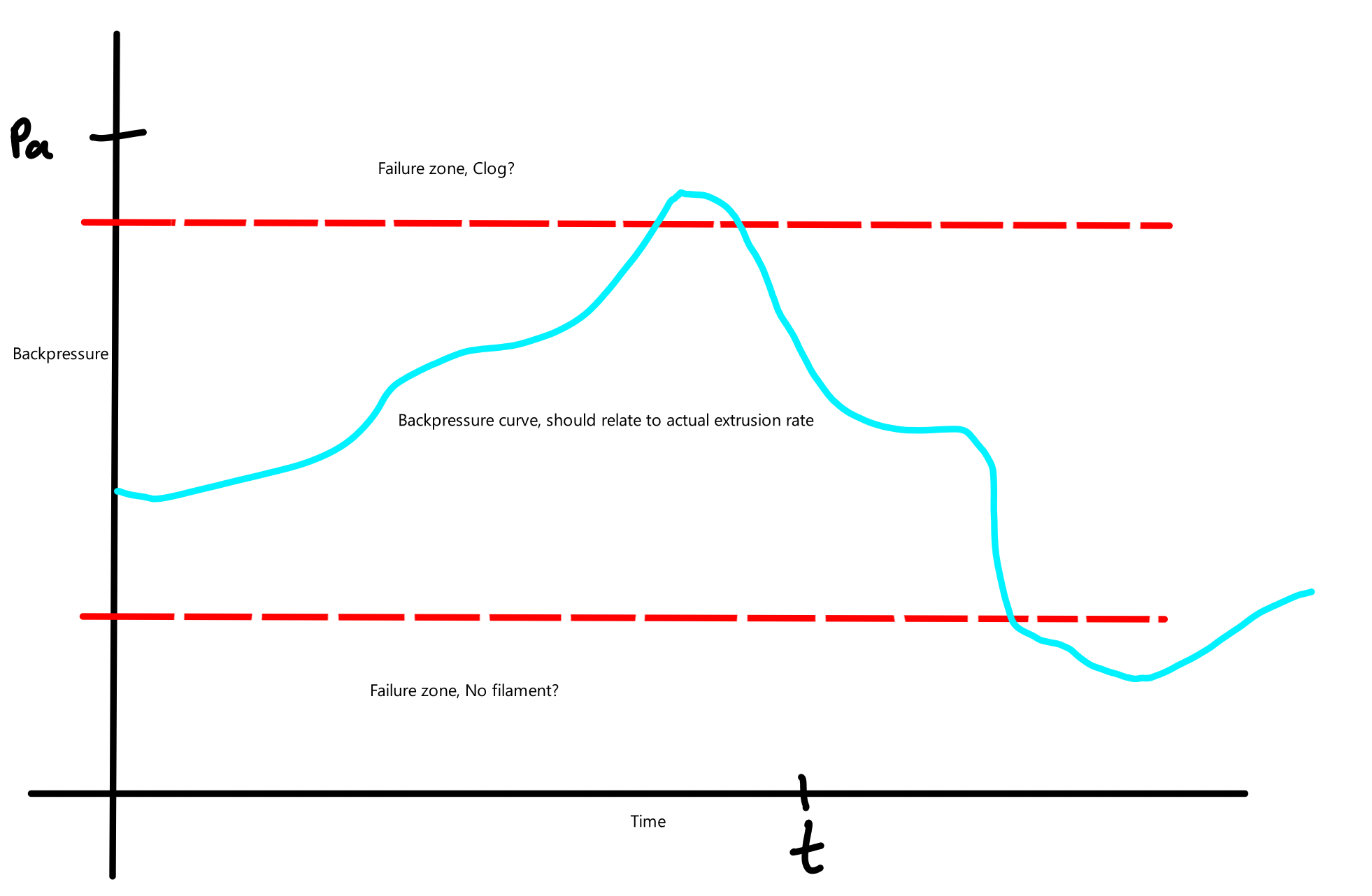

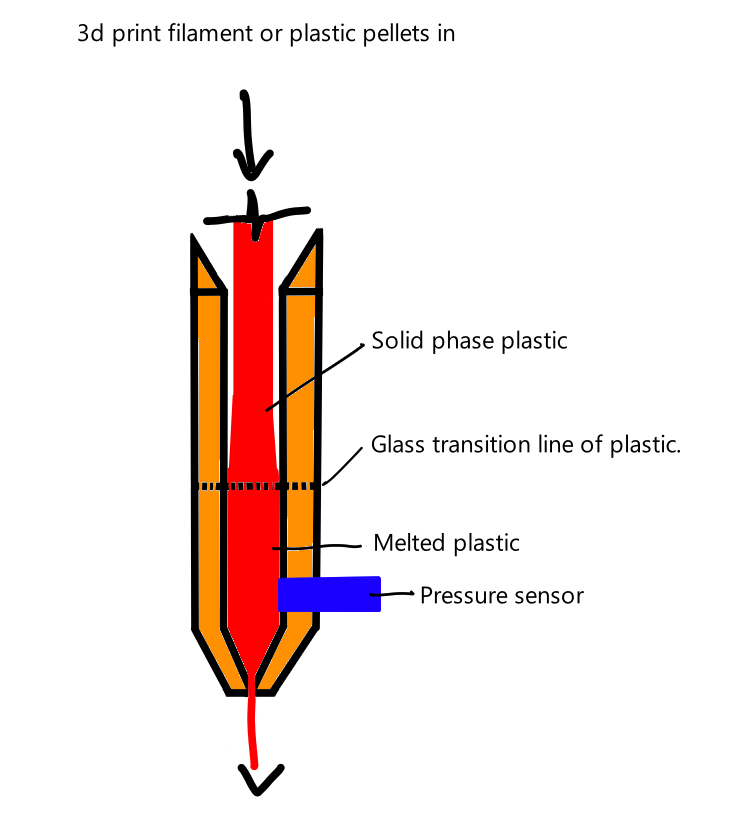

Adding a pressure sensing element inside a 3d printing hotend would allow for direct feedback on extrusion allowing for a closed loop control system. By adding a pressure sensor after the glass transition zone of the hotend where the plastic is molten we can measure the backpressure. The backpressure could be monitored by the 3d printer controller to determine several failures during printing(no plastic, hotend clog/too rapid extrusion rate, etc). The backpressure should correlate directly with volume of extrusion when keeping the melt zone temp constant. A 3d print controller could dynamically change actual speeds and feeds of the machine during printing for faster, more consistent, and higher quality prints. The system could be used in specialty extruders like pellet extruders or extremely large volume extruder heat zone to much more accurately and directly control extrusion (helpful for retractions and hops to make sure non-desired plastic extrusion is controlled). A ring piezo around the perimiter of the extruder or a pressure sensor to one side of the hot end would allow for measuring pressure from a voltage. There's undoubtable some issues in size and induced turbulence from having an additional thing in the hotend, but I think they could all be easily overcome.

email: va.web.code@gmail.com https://github.com/va-code https://www.youtube.com/@vaughnanderson7984