/ /AluminumCasting /MechContrSyst /ParametricSlicing /AluminumCarving /Thermodynamics /FEA /SPE3Dprinting /ElectricMotorcycle /3dPressureSensingHotend /PopsicleBridge /Ramjet /ModelSterling /3DPrintedDiscGolf /Bonsai /DamascusRing /Drawings /MetropolisFEA /Python /Ceramics

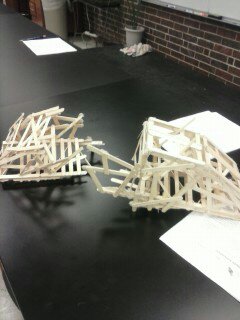

There was a popsicle bridge building contest in a highschool class that I wasn't part of. I took offense personally. I can build a pretty good bridge, not only that but the rules were extremely lax and ready for manipulating. So once again, my classmate and I asked if we could participate in this bridge building contest. These fools, these... these children were building bridges that didn't even look like bridges. A sad, sorry state of affairs. There was nothing to be done but to outdo them in every way. And to top it off we decided we wanted our bridge to be a draw bridge split down the middle. Now that is showing the competition what for. Our bridge isn't even going to be fully connected we thought, puts all yours to shame. Now back to the rules of the competition. There were none, except that you had to use popsicle sticks and a gluegun. A smart person would overbuild the bridge to high heaven, but none of the competition did. Rest assured, we used an inordinate amount of glue and sticks. Easy, arched truss bridge here we come. Turns out the hard part about the draw bridge is connecting the drawbridge, especially when you don't anchor down the ends. We ended up mostly giving up on that, we glued the halves together at the locking joint we made when actually testing the bridge. Yep... they didn't have enough weights to break the bridge. So I stood on it. That didn't break it, so it could cary at least 140lbs. My teammate stood on it and it started to give and crack so ~170 lbs. It did take a little dynamic loading to break it though, my teammember bounced up and down lightly and it shattered.

email: va.web.code@gmail.com https://github.com/va-code https://www.youtube.com/@vaughnanderson7984